Gas Springs

Typical areas of use include controlled opening and closing of hatches and hoods. But they can be equally adept at controlling complete equipment such as ventilation apertures, chairs, beds, windows, tools and machinery etc.

Home » Technology » Gas Springs

Technical information of gas springs

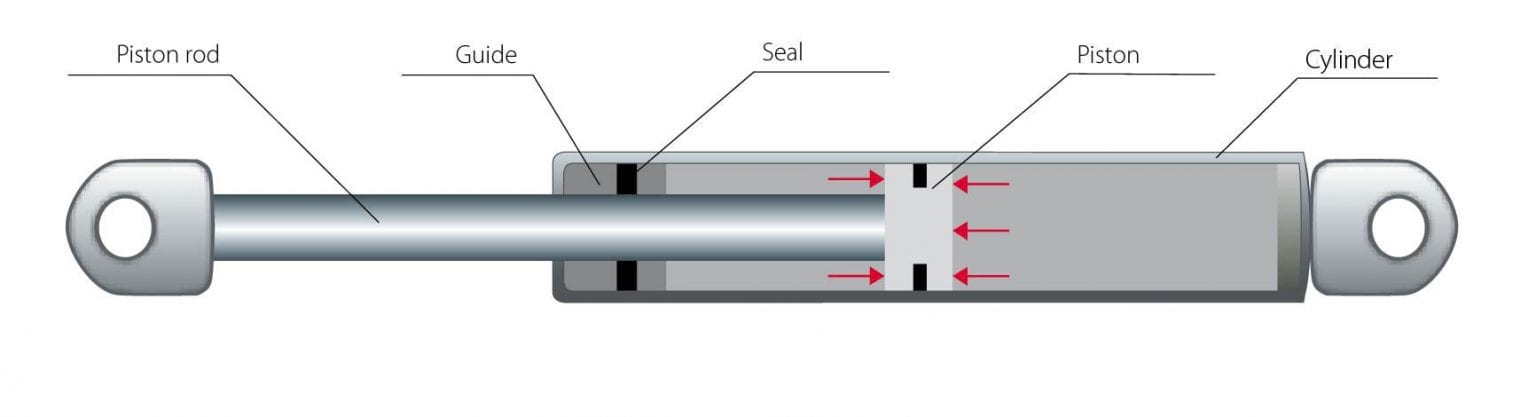

The main components of a gas spring are a cylinder, a piston rod with piston head, a seal and a guide.

The cylinder is filled with compressed nitrogen gas, which applies equal pressure on both sides of the piston. The surface of the piston rod side of the piston is smaller than on the opposing side, producing a pushing force. In simple terms, the magnitude of the driving force is determined by the cross-sectional area of the product’s piston rod and the internal pressure inside the cylinder.

Gas spring characteristics

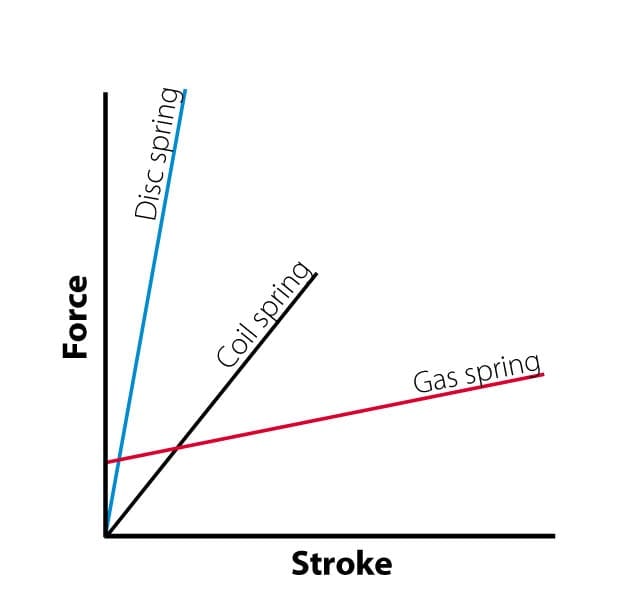

In contrast to most other types of springs, gas springs have a built-in pre-tension force and a flat spring characteristic. This means that there is only a small difference in force between full extension and full compression.

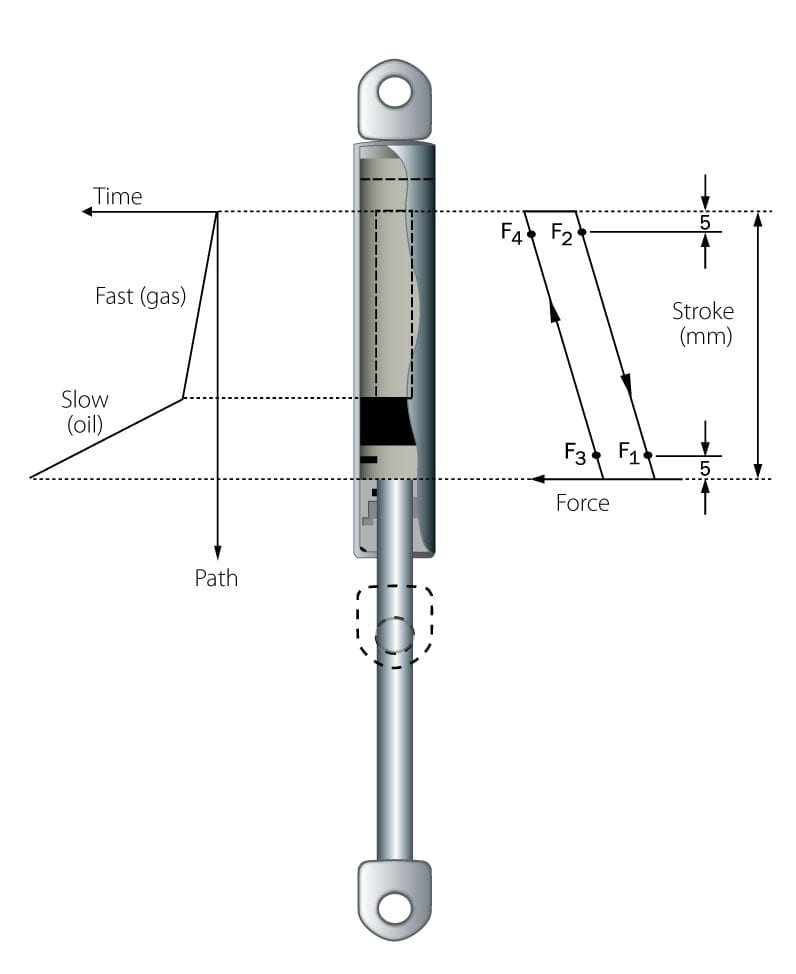

As the piston and piston rod are pressed into the cylinder, volume reduces and pressure increases. This causes pushing force to increase. In conventional gas springs, this increase is normally around 30% at full compression. The diagram illustrates, in simple terms, forces F3, F4, F2 and F1 along the stroke when the gas spring is fully compressed and then released. F1 indicates the force just before full extension.

It is this static F1 force we refer to when we talk about the force of a gas spring. The difference between force pairs F3/F1 and F4/F2 varies according to the amount of friction.

The pushing spring movement is slow and controlled. It is reliant on the gas flow between the piston sides being allowed to pass through channels in the piston during the stroke.

Conventional gas springs use ‘hydraulic damping’, which involves a small amount of oil slowing down the speed of the stroke immediately before the spring reaches full extension. This gives the movement a braking character at the end position provided that the piston rod is in the downward direction.

Force calculations of gas springs

Using a software package developed in-house, Lesjöfors is able to simulate any type of application imaginable, enabling us to quickly help calculate the force requirement for your particular design of your gas springs.

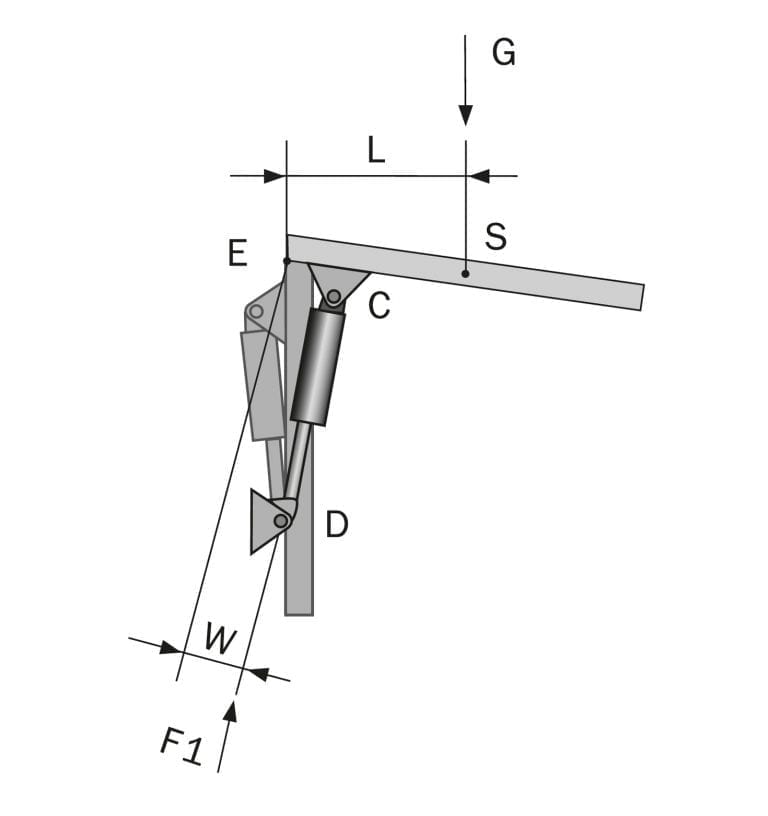

In simpler cases, the required gas spring force may be calculated by entering relevant values into the following formula:

F1 = (G x L) / (W x n) + 10 – 15% margin of error

Variable | Description |

|---|---|

F1 | Gas spring force in Newton |

G | Gravitational pull in Newton of the moving part |

C | Connection point on the moving part |

D | Connection point on the fixed part |

E | Swivel point |

S | Centre of gravity |

L | Horizontal distance from E to S in open position |

W | Smallest distance to E |

n | Number of gas springs |

For quick and effective assistance, please fill out this design applications form and send to us

Force tolerances

Tolerances when charging with gas and other factors mean that there may be variations in the force exerted by gas springs with the same nominal F1 value. The tolerances in the table below are excessive; the actual forces are usually very close to the nominal specification.

Force tolerances (N)

Force (N) | tolerance |

|---|---|

F1 ≤ 100 | +/- 10 |

100 < F1 ≤ 200 | +/- 20 |

200 < F1 ≤ 600 | +/- 30 |

600 < F1 ≤ 1200 | +/- 50 |

F1 > 1200 | +/- 100 |

Force tolerances (N) 12-4

Force (N) | tolerance |

|---|---|

F1 ≤ 50 | +/- 5 |

50 < F1 ≤ 100 | +/- 10 |

F1 > 100 | +/- 15 |

Note that if the ambient temperature rises or falls, the force of the gas spring rises or falls depending on pressure changes in the cylinder.

Temperatures

The nominal F1 values apply at 20° C, which is the temperature at which gas charging is carried out. As a rule of thumb, gas spring force increases by approximately 3.5% per 10° C temperature increase and reduces accordingly when the temperature falls.

Lifetime of a gas spring

Lesjöfors gas springs are generally permitted to have a maximum force loss of 10% after 40000 cycles at a max of five cycles per minute at room temperature and in ideal fitting circumstances.

However, it must be remembered that gas springs have a shelf life as the sealing material ages and wears out. There are several factors that affect gas spring lifespan in an application.

External factors such as temperature changes and other physical environmental influences can affect seal aging and wear and thereby speed up the process of force loss.

In addition, fitting also plays a significant role. If, for a majority of its operational life, a gas spring has its piston rod pointing downwards, the seals and the piston rod will be kept lubricated with oil, thus minimising wear and leakage.

A gas spring will also last longer if it is fitted free from vibrations and in such a way that no lateral forces can be produced.

A good rule for a designer is to always choose a gas spring with the largest possible cylinder volume for the amount of force required.

Advices for the use of gas springs

1. Gas springs are pressure vessels. Never try to open one without following the instructions in the section entitled “Recycling”. Never expose a gas spring to excessive heat or naked flames.

2. To ensure the optimal function and lifespan, conventional gas springs should be fitted so that the piston rod always, or as frequently as possible, points downwards during use. If the piston rod is down at the end of the stroke, the hydraulic damping is used to the full.

3. Gas springs must not, under any circumstances, be exposed to damaging external influences or violent handling. Lesjöfors accepts no warranty or return liability for the following:

3a. Visible damage to the piston rod, including minor scratching, paint dust, bending or similar. This may damage seal function.

3b. A damaged cylinder. This may mean that functionality has been jeopardised and may pose direct safety risks. Never try to use a gas spring that exhibits tiny dents or bends on its cylinder. Take it out of use and follow the instructions in the section entitled “Recycling”.

3c. Gas springs where either the warning text, manufacturing date or part number has been removed by external action.

4. Our gas springs are designed for ambient temperatures of between -30 and +80°C. If possible, avoid intensive use at the extremes of this temperature range. Reducing/increasing ambient temperature also means a reduction/increase in gas spring force.

5. Gas springs are designed to handle axial loads. Avoid radial forces (lateral forces). Choose as big a cross section as possible.

6. We always recommend the use of external end stops in the application. Do not exert any external force during the stroke.

7. Do not lubricate the piston rod with grease or oil, and do not expose the gas spring to oils or solvents.

8. Avoid using non-stainless gas springs in corrosive environments.

9. Do not expose the piston rod to dirt and dust.

10. Long periods of storage may cause the sealing material to age. If storage is necessary, we recommend you adopt a “first in – first out” policy. If a gas spring has been unused for a long period of time, it may require a little more force to press the piston rod in when operated for the first time. This is normal and does not have a negative impact on future use.

If all these points are taken into account, you will have gone some way towards safe and well-functioning use of gas springs. However, Lesjöfors cannot be held liable for the performance or safety of the final application.

Recycling a gas spring

The majority of gas springs are made of metal and therefore can be recycled. If you are going to dispose of a gas spring yourself, e.g. if it has been damaged or has otherwise become unusable, bear in mind the following:

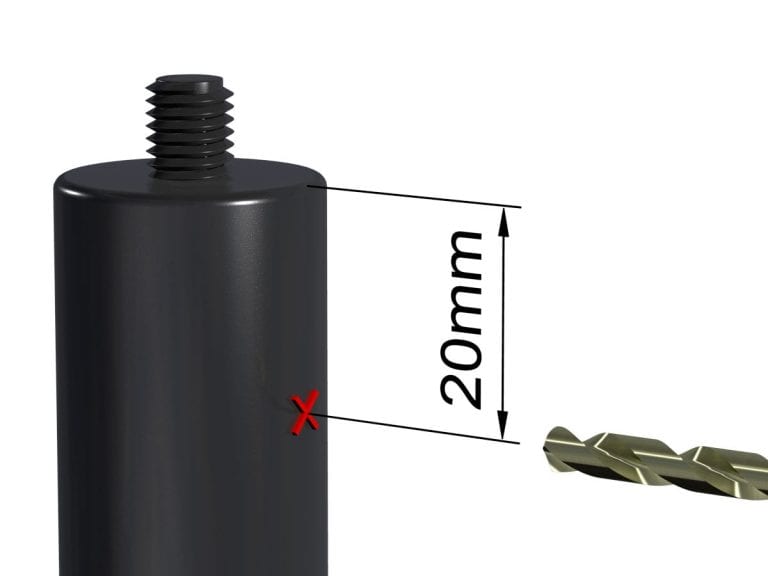

1. Depressurise the gas spring by drilling a 3 mm hole 20 mm from the cylinder end with it fixed in the vertical position and the piston rod down and in max extended position. NB Wear protective goggles, protective clothing and ear defenders when doing this as the spring will make a noise when pierced and you may be exposed to small amounts of oil and metal fragments.

2. Drain the oil through the drilled hole by pressing in and pulling out the piston rod repeatedly if necessary. Recycle the waste oil in accordance with local regulations.

3. The gas spring can now be taken to a metal recycling centre in accordance with local regulations.