Our ambition is to be the most sustainable spring and pressing company in the world

Sustainability in mind.

Our ambition is to be the most sustainable spring and pressing company in the world. We know manufacturing has a major impact on our environment and this is why we are striving towards a more sustainable future and have set climate targets in line with the Paris Agreement which are now validated by the Science Based Targets initiative (SBTi).

Climate-related issues are high on the sustainability agenda for everyone, and we want to be transparent about the progress we are making across our whole value chain, including introducing lower carbon footprint products.

Sustainability

focus

We are intelligently linking and analysing data across all our global operations, benchmarking how sustainable we are today and setting milestones to shape greater sustainability for tomorrow.

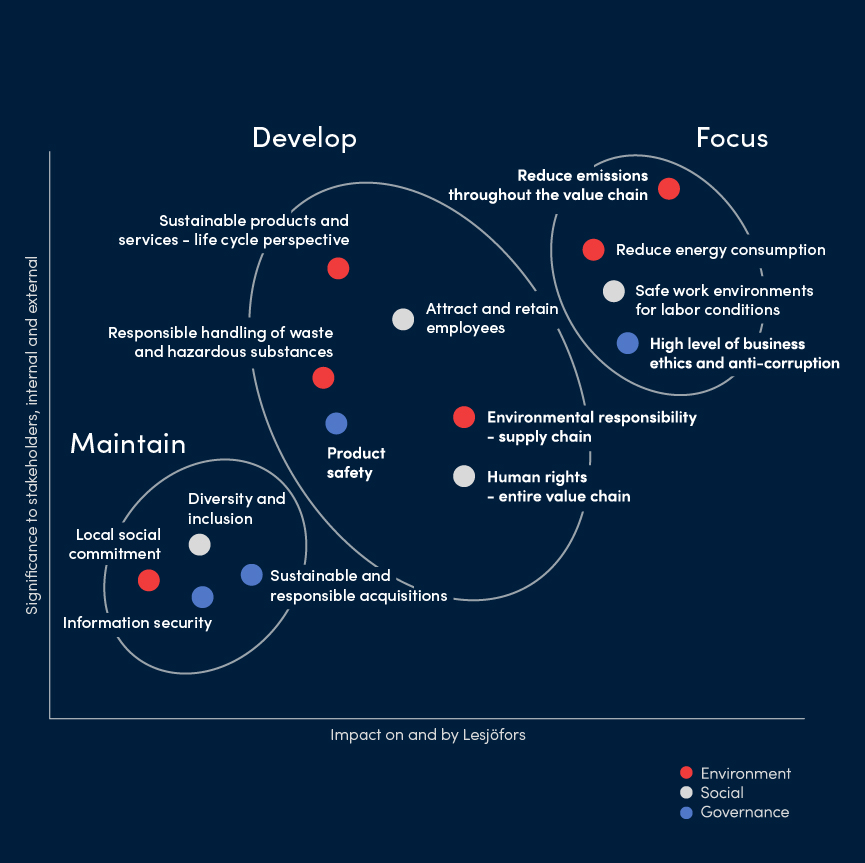

Environmental, Social and Corporate Governance (ESG) is becoming increasingly important. In 2021, to embed the ESG criteria into our group’s strategy, we surveyed our stakeholders to quantify the areas of sustainability we should focus on, develop and maintain. The results launched our roadmap to 2030.

Towards 2030

To achieve our sustainability ambitions with integrity, we need to ensure that sustainability is integrated efficiently across all our operations. To do this, we need to define how our business can collaborate with partners to bring about large-scale change in the sustainability space.

To be a better business for people and planet, we need to focus on our impact over a realistic duration.

Roadmap

towards 2030

We are on a sustainability journey. It started in 2012 and we have been focusing on different projects and initiatives ever since. We believe we are on the right track.

2012-2018

- Committed to the principles of the UN Global Compact

- Climate Disclosure Progress Report (CDP)

- Code of Conduct Developed

- Sustainability accounting system developed

- First sustainability report (issued by Beijer Alma)

2019-2022

in biogas

- Updated sustainability goals

- Code of Conduct training

- Scope 3 reporting started

2023-2030

- EcoVadis assessment

- Greenhouse gas accounting full value chain

- Climate commitment in line with the Paris Agreement validated by Science Based Target initiative

- Climate reduction roadmap in place

How we are going to do it

We are finding solutions and we are making changes.

Our sustainability work is focused on five key areas:

Involvement in our society and communities across educational and charitable organisations, universities and industry associations links innovation and talent management, adding value to our teams and our social responsibilities.

In 2022, we have created a sanction policy and established a digital support system for risk-based supplier assessments. We are also training our MD’s and staff regularly on news and changes concerning Environmental, Social and Corporate Governance (ESG).

Code of Conduct Beijer Alma (PDF)

Whistleblowing Report

Energy audits across sites build our future action plans as we work to optimise and reduce energy consumption further. Action to date includes enhanced efficiencies in ventilation control, LED lighting installations, solar panel installations, upgrading to more modern and efficient machinery and individual energy meters implemented across machinery.

We’re also working closely with our customers to offer energy-efficient solutions through optimised design and low-carbon material choices.

Investments in energy efficiency and renewable energy are made on a regular basis to further reduce our carbon dioxide emissions. We follow and initiate dialogues with our supplier base about sector development in the transport and steel industry.

We are working to enhance our product development process, which takes place in close collaboration with customers, in order to clarify the product life cycle perspective and climate footprint. Collaboration in the value chain is key for finding ways forward and we value supplier engagement to increase the share of recycled metals and lower greenhouse gas footprint metals in our products.

Reduce climate impact in the value chain

- Reduce emissions, direct and indirect within our operations (Scope 1 & 2)- Reduce emission footprint of our products and services in the value chain (Scope 3)

Discover some of the CO2 emission reduction changes we have implemented across our factories:

- Accelerating sustainability with a greener energy mix and emission reductions or

- Lesjöfors factory takes steps to reduce its climate footprint using bio fuel

We have introduced new methods for performance and development support and have created opportunities for adapted and integrated learning that promotes CPD through our recently launched Lesjöfors Academy. The Lesjöfors Academy is an exciting new initiative to ensure continuous growth and development across employees and managers, further enriching our teams across all training levels.

We believe transparency across business is not only ethical but essential and by providing open access to our processes, policies, guidelines and everyday operations, we are forging loyal partnerships with our customers and suppliers.

We have a digital process for the control and follow-up of supply chain ESG risks with a Business Partner Code of Conduct.

We also have a Whistleblowing Channel (run by our owner Beijer Alma).

Our engineers are developing our services, so we can design and deliver quality solutions with minimal manufacturing climate impact, in materials that are more sustainable.

Our ambition is to expand our low-emission product range.

Read more about our pilot projects in the group about Life Cycle Analysis and Eco-Design

Sustainability with high ambition

“We have taken a big step forward in our strategy to build a modern Lesjöfors, integrating sustainability as one of our core elements to show that we take the issue and the impact on people and planet very seriously. We believe this will not only strengthen our stakeholder relationships and market position, but also drive our own personal ambition and ultimately contribute to a better world in the future.”

Ola Tengroth

CEO Lesjöfors Group

version 01// Lesjöfors science-based emission reduction target

We have committed to a climate reduction roadmap by setting emission reduction targets grounded in climate science through the Science Based Target Initiative (SBTi), in line with the Paris Agreement. We have sent in our near-term targets for 2030 and we’ve already started moving forward with our local reduction plan. These climate targets will minimise the GHG emissions throughout our value chain.

We began assessments of the climate impact throughout our value chain in 2021, analysing our groups CO2 emissions in association with our use of raw materials – mainly across metals and plastics in our component manufacturing process.

version 02//Lesjöfors is preparing for science-based targets in line with the Paris agreement.

Lesjöfors implements a wide range of measures to reduce the negative impact from our operations on the climate and to drive positive change. We have an ambitious sustainability strategy and climate action is one of our priorities. We have finalised our complete greenhouse gas accounting during 2022 and we have set a climate reduction roadmap towards 2030. We focus our efforts on where they will have the greatest impact. Investments in energy efficiency and renewable energy are made on a regular basis to further reduce our carbon dioxide emissions.

We follow and initiate dialogues with our suppliers about the sector development in the transport and steel industry. We are working to enhance our product development process, which takes place in close collaboration with customers, in order to clarify product life cycle perspective and climate footprint. Collaboration in the value chain is key for finding ways forward and we value supplier engagement to increase the share of recycled metals and lower greenhouse gas footprint metals in our products.

Lesjöfors gets validation of science-based targets in line with the Paris agreement

Lesjöfors implements a wide range of measures to reduce the negative impact from our operations on the climate and to drive positive change. We have an ambitious sustainability strategy and climate action is one of our priorities. We focus our efforts on where they will have the greatest impact. Investments in energy efficiency and renewable energy are made on a regular basis to further reduce our carbon dioxide emissions.

In 2021 we began assessments of the climate impact throughout our value chain, analysing our groups CO2 emissions in association with our use of raw materials. During 2022 we have finalised our complete greenhouse gas accounting.

We have committed to a climate reduction roadmap by setting emission reduction targets grounded in climate science through the Science Based Target Initiative (SBTi), in line with the Paris Agreement. Our near-term targets for 2030 have now been validated by SBTi. These climate targets will minimise the GHG emissions throughout our value chain. In addition, we have already started moving forward with our local reduction plan.

Following and initiating dialogues with our suppliers regarding sector developments in the transport and steel industry is a key focus. Our efforts are directed towards improving our product development process, a collaborative effort with our customers, to provide clarity on product life cycle perspective and climate footprint. Collaboration in the value chain is key for finding ways forward and we value supplier engagement to increase the share of recycled metals and lower greenhouse gas footprint metals in our products.

We are calculating and mapping, following a cradle-to-gate approach across Scope 1 (direct emissions of energy or heat generated directly by the company and from the use of company facilities and vehicles) and Scope 2 (indirect emissions including purchased energy, steam and heat). These are the key areas we are focusing on first. We have also started to more accurately map emissions in Scope 3 categories (upstream and downstream activities concerning our customers, suppliers and transport), examples of which include the purchasing of goods and raw materials, transportation and waste. These account for the largest share of emissions in our value chain.

We are calculating and mapping, following a cradle-to-gate approach across Scope 1 (direct emissions of energy or heat generated directly by the company and from the use of company facilities and vehicles) and Scope 2 (indirect emissions including purchased energy, steam and heat). These are the key areas we are focusing on first. We have also started to more accurately map emissions in Scope 3 categories (upstream and downstream activities concerning our customers, suppliers and transport), examples of which include the purchasing of goods and raw materials, transportation and waste. These account for the largest share of emissions in our value chain.

“Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

(Brundtland Report, 1987)

Collaboration is key

to innovation

We have got a lot of work yet to do and partnerships are key to the successful implementation of our comprehensive sustainability programme. By working together with our customers, suppliers, distributors, and energy producers we can develop new mutually beneficial opportunities for the climate and for each other.

We are on our way and this is the next phase of Lesjöfors’ significant investment in digitalisation and automation, offering a connected industrial ecosystem that enables us to understand the carbon intensity and resource utilisation, upstream and downstream, across our value chain.

Powering

sustainable solutions

From leaf springs in space satellites tracking climate data to gas springs in disability ramps to extension springs in electric generators for windmills and to compression springs for EV bikes and cars, our products power sustainable solutions.

Across the world’s power generation network, you have springs, pressings and wire forms sitting at the heart of sustainable solutions.

Suspension Spring

read story

Gas spring

read story

Suspension Spring

read story

Extension Spring

“Sustainability has been part of who we are for a long time. So much so, that a few years ago, one of our employees had the idea to make some of our outdoor areas a better place for all kinds of animals. We knew they were on to a good idea and so we converted 4000 sqm of land into a biodiversity area. This green space is blossoming with wildflowers, grasses and seeds and we now have a wide variety of animals, including many different birds, insects, hedgehogs, butterflies, rabbits and a family of foxes and sometimes even a deer or two.”

4000 sqm of biodiversity

Joan Jensen

Managing Director

Lesjöfors A/S Tinglev, Denmark

Lesjöfors Voices

“I especially enjoy speaking to the workforce about sustainability, and the reasons we are implementing changes; the engagement from the employees is fantastic. All our workforce understands the need to reduce our footprint and to be a responsible employer. We have implemented a number of initiatives, such as switching our electricity supply to a mix of Renewable and Nuclear, which has reduced our Scope 2 emissions to zero, or moving our natural Gas supply to a mix of Biogas and natural gas, which has reduced our Scope 1 emissions by 10%.”

Getting employees onboard

David Purvis

HR Manager

European Springs and Pressings Ltd., UK

Lesjöfors Voices

"At Alcomex, we’ve taken considerable steps towards sustainable production processes, by significantly reducing our Scope 1 and 2 CO2 emissions. We’ve tracked emissions, set goals, and collaborated to achieve this. I believe, that as a company, we can make a substantial impact for a sustainable future, and as individuals, each of us can also contribute positively."

Driving sustainable change

Nicky Spijker

QHSE Coordinator

Alcomex, Netherlands

Lesjöfors Voices

Global Mind. Local Heart.

Evidencing our strategic sustainable actions and where we are on our roadmap, is just a small part of our transparency, showing the steps we are taking and where we are aiming towards. Explore our news section to see sustainable changes taking place across our operations.

News

Focus on supplier engagement is key on our decarbonization journey

Supplier engagement is important for all companies committed to the Science Based Target initiative (SBTi). Lesjӧfors works strategically with partnerships and prioritizes suppliers that can provide metals and transport with low CO2 emissions.

News

New electric freight logistics service cuts CO2 emissions by 95%

Automotive AB, the Nordic logistics hub for Lesjöfors’ Automotive Aftermarket, has significantly cut its scope 3 emissions with help from packaging supplier, Stora Enso.

News

Lesjöfors Group becomes first spring manufacturer to be validated by SBTi

In a first for the spring manufacturing industry, the Lesjӧfors Group’s near-term climate emission reduction targets have officially been validated by the Science Based Target initiative (SBTi).

Questions?

Get in Touch!

We are working together with so many partners and customers to discover new beneficial opportunities for our business and planet.

Our ambitions are supported by our sustainability team led by Anna Haesert, Head of Sustainability and Bianca Plankenhorn, Sustainability Manager.

If you would like to share our journey to a more sustainable future, please do not hesitate to get in touch at

“Sustainability is about looking at the big picture and figuring out how we can contribute to a circular, sustainable society, monitoring technological developments around us, and valuing partnerships and collaboration. As Head of Sustainability, my role is to develop and accelerate the strategic focus on sustainability towards a full value chain and sustainable value proposition. Sustainability work is an important foundation for all Lesjöfors‘ operations, and we focus on areas where we can add value for our customers while ensuring that we take full responsibility for our impact. We as adults in today’s society have a role to play, both as representatives of our company selling our products and as individuals acting on the best available knowledge, listening to what science has to say and ensuring the best for the coming generations.“

Anna Haesert

Head of Sustainability

Download

We are actively collaborating with our customers, suppliers and partners, striving to be the most sustainable spring and pressing company. We believe in transparency and accountability and that’s why we hold the partners in our value chain to the following set of standards.

Whistleblowing

The corporate climate must be transparent, with a high level of business ethics. As such, we want to identify any potential irregularities at an early stage. Through our whistleblowing process, employees and stakeholders can report suspected unethical behaviour or illegalities safely and entirely anonymously.

This is a service run by our owner Beijer Alma.

Frequently Asked Questions

Lesjöfors works on sustainability to create value for customers and stakeholders. We help customers address climate issues and reduce their environmental impact. We develop components and services with a lifecycle perspective in close dialog with customers.

To drive customer value through sustainable springs & pressings solutions. Lesjöfors sustainability work is focused on five areas – sound business ethics and social commitment, more efficient use of resources, reduced climate impact, and a safe and stimulating work environment and innovation with sustainability in mind.

Lesjöfors is aware of how its operations affect people, society and the environment. We strive to create value that meets the needs and expectations of our stakeholders, while also taking into account the financial, environmental and social consequences of our actions. To do this, we conduct stakeholder and materiality analyses that follow the requirements of the Global Reporting Initiative (GRI) and the new EU Corporate Sustainability Reporting Directive (CSRD), which include applying a double materiality analysis and engaging in dialogs with key stakeholders.

You can reach our sustainability team on sustainability@lesjoforsab.com.