Medical

Springs and pressings for medical technology. Certified production under highest cleanliness requirements.

Home » Industries » Medical

Medical Technology is in our DNA

Lesjöfors manufactures and supplies the medical industry with springs and pressings from wire or strip material for disposable medical products, medical equipment and hygiene-related products.

We have a expansive network of production plants around the world with exceptional expertise and equipment dedicated to the medical sector.

Regardless of the quantity and application, we offer innovative solutions for manufacturing, cleanliness, packaging and automation.

Our medical technological high-quality standards are achieved through state-of-the-art production facilities and production technology, a large range of products, use of the latest laboratory technology and certified standards.

Compression Springs

Constant Force Springs

Power Springs

Compression Springs

Power Springs

Constant Force Springs

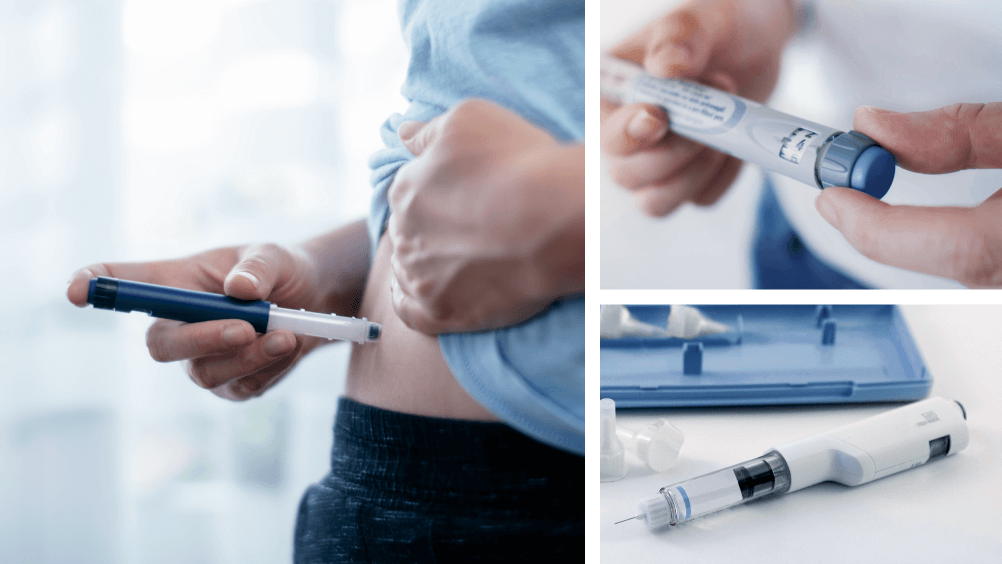

Injectors for

drug administration

Autoinjectors, drug delivery devices, or pen injectors utilise compression springs, power springs, constant force springs, deep drawn parts as well as stampings and bending parts.

The use of technical springs ensures exact dosing of the drug as well as a high level of safety for the user. We offer automated and clean manufacturing solutions in spring technology for economical large-scale production with standard or special packaging.

In the production of our springs, we use state-of-the-art camera technology to ensure the manufacturing process and compliance with spring tolerances. In addition to technical cleanliness, we are also familiar with the requirements for organic and biological cleanliness in the field of medical technology.

Blood Lancet Devices

Compression springs, stampings and bending parts are commonly an integral component part in blood lancet testing units. These components deliver critically precise accuracy with certified technical cleaniness and are used to gain safe access to the blood. Our controlled ‘clean-room’ production environment guarantees the function and cleanliness of our springs, stampings and bending component parts. Consistent quality management is achieved through specifically designed washing and packaging concepts. Our medical manufacturing capabilities feature a high degree of automation, enabling efficient series production tailored to your project requirements.

Compression Springs

Compression Springs

Compression Springs

Constant Force Springs

Bending parts

Compression Springs

Constant Force Springs

Bending Parts

Continues Glucose Monitoring

For continuous glucose monitoring, a sensor is placed under the skin. The latest generation of Glucose Monitoring (CGM) devices use an attachment that is controlled by constant force springs or compression springs. Precisely calculated torques and pressure forces ensure that the sensor is attached safely and comfortably.

Sustainability is a priority at Lesjöfors. We continously monitor our environmental impact through data analysis of our on-site production plants and our local supply chains.

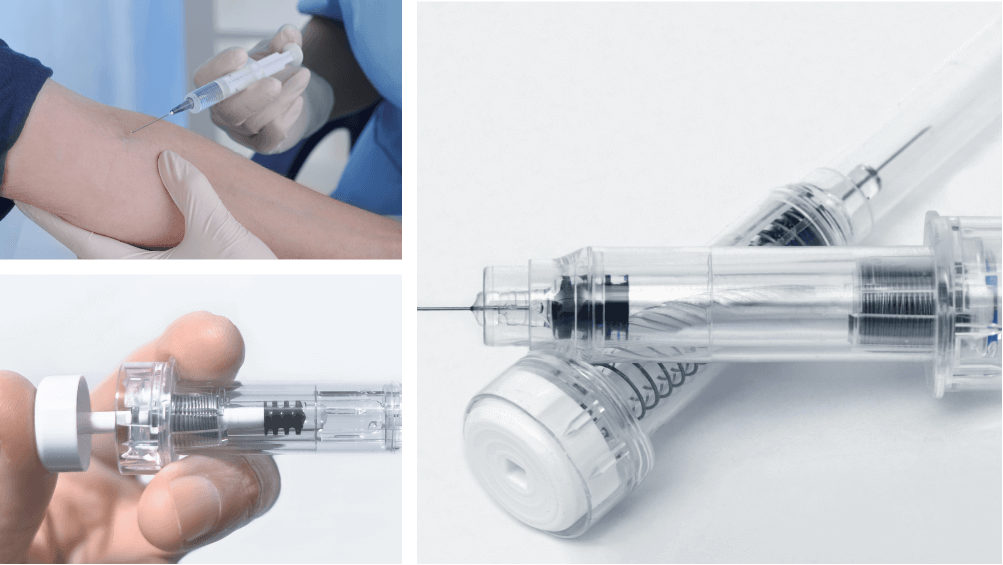

Syringes

Syringes for medical technology mainly use compression springs. Release and retraction mechanisms of safety syringes, or needle shields, are controlled by spring technology. Depending on the application and specification, we configure and calculate the optimum material grade and spring design.

Essentially, stainless steel materials in different material grades and surface finishes are used. Right from the start of the project, we take into account the spring separation, cleanliness requirements and series packaging as well as the further processing of the spring in the final assembly process.

Compression Springs

Compression Springs

Compression Springs

Compression Springs

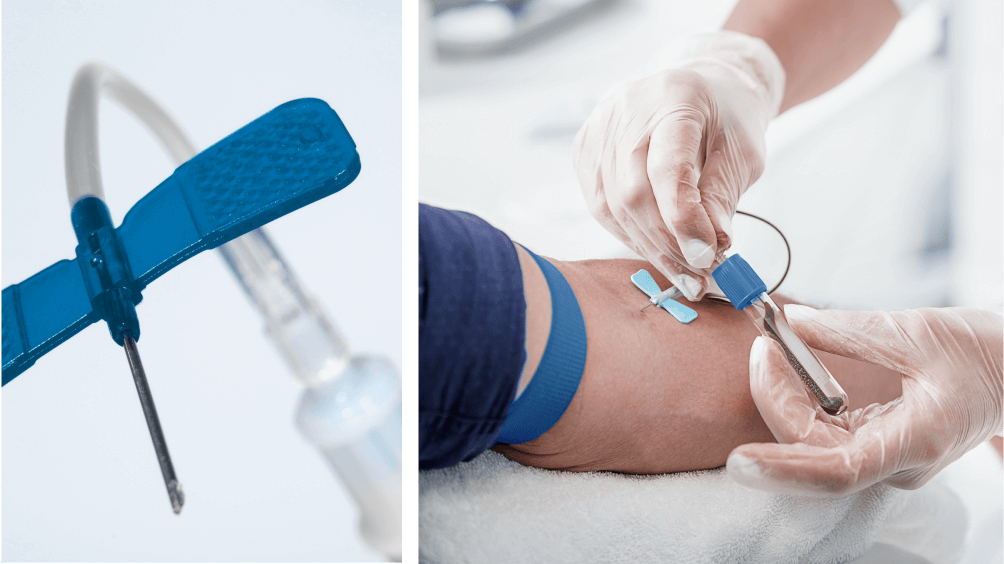

Blood collection and infusion technology

One of the newest and most common ways of venous blood collection and infusion is via winged cannulas (butterflys). To avoid unintentional transmission of infection caused by needle sticks, winged cannulas are increasingly being equipped with needle retraction systems, or needle shields. The needle retraction is controlled by a compression spring.

In the field of medical technology for blood collection, we work with the highest requirements in terms of technical and organic or biological cleanliness. We achieve this through special spatial conditions and automated spring production.

Diagnostic and laboratory equipment

Like the variety of our springs, pressings, stampings and bending parts, the applications in the field of diagnostic and laboratory equipment in medical technology are almost unlimited. Examples for the use of our springs would be applications in the field of radiology (MRT), lancing devices, and blood glucose meters.

Our equipment in the field of medical technology is also ideally suited for medium and small production batches. Our expertise in spring technology for diagnostic and laboratory equipment covers the entire product development process, from the manufacture of sample parts to series production.

Compression Springs

Power Springs

Bending Parts

Compression Springs

Power Springs

Bending Parts

Compression Springs

Inhalers and pump sprays

Depending on the design, compression springs, pressings, bending parts and stampings are used for inhalers and pump sprays in the medical field. The requirements for technical cleanliness, organic cleanliness and biological cleanliness are particularly high here.

We therefore manufacture these products under special cleanliness and hygiene conditions. We offer a complete cleanliness chain from the selection of suitable materials, manufacturing processes, packaging concepts to residual dirt analyses. For this area of our product portfolio, we are a full-service provider and take over all stages of the value chain.

Medical equipment

Technical springs, pressings, bending parts, stampings and gas springs are an integral part of medical technology. They are used in a wide variety of applications from one offs to high volume quantities.

Our products are used extensively within the medical environment and some examples include; compression springs for hospital beds, power springs for climbing aids, stampings for patient transport trolleys, constant force springs for automatic fall detection systems, wire forms for prostheses, bending parts for hearing protection and many more.

Gas Springs

Power Springs

Stampings

Power Springs

Stampings

Gas Springs

Wire Forms

Compression Springs

Wire Forms

Compression Springs

Medical hygiene products

Requirements in the field of hygiene are becoming increasingly important. We supply customers in medical technology, cosmetics and sterilisation. Our technical springs play a major role in ensuring that the hygiene products are safe. In addition to the requirements for cleanliness, the precision and service life of our springs also play an important role.

Applications for medical hygiene products include soap dispensers, disinfection dispensers, paper towel dispensers, fragrance dispensers and various cosmetic applications. With our locations in Europe, Asia and the USA, we meet the highest standards of quality and delivery performance.