Medisinsk teknologi

Fjærer, tråddetaljer, stansing og forming for medisinsk teknologi. Sertifisert produksjon under de høyeste renhetskrav.

Medisinsk teknologi

Tekniske fjærer, bøyde deler og stansede deler for medisinsk teknologi. Sertifisert produksjon under høyeste krav til renslighet.

Lesjöfors produserer og leverer alt fra tekniske fjærer, bøyde og stansede deler av metalltråd eller båndmateriale til medisinske engangsprodukter, medisinsk utstyr og hygienerelaterte produkter til legemiddelindustrien.

Til dette formålet har vi flere produksjonsanlegg rundt om i verden med ekspertise og utstyr for ditt medisinske prosjekt.

Uavhengig av mengde og bruksområder tilbyr vi innovative løsninger for produksjon, renslighet, emballasje og automatisering.

Vi oppnår vår høye kvalitetsstandard innen medisinsk teknologi gjennom førsteklasses produksjonsanlegg og produksjonsteknologi, et stort utvalg produkter, bruk av den nyeste laboratorieteknologien og sertifiserte standarder.

Trykkfjærer

Konstantkraftfjærer

Drivfjærer

Trykkfjærer

Drivfjærer

Konstantkraftfjærer

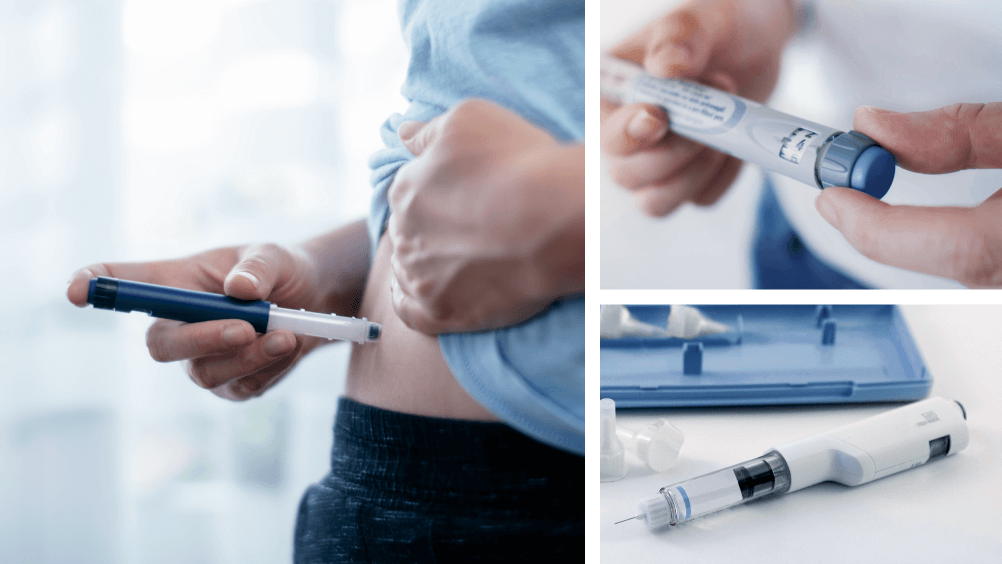

Injektorer for medikamentadministrasjon

Autoinjektorer, legemiddelleveringsenheter eller penninjektorer bruker trykkfjærer, drivfjærer, konstantkraftfjærer, dyppressede produkter, samt stansede detaljer og stansede fjærdetaljer.

Bruk av tekniske fjærer sikrer nøyaktig dosering av legemidlet samt et høyt sikkerhetsnivå for brukeren. Vi tilbyr automatiserte og rene produksjonsløsninger innen fjærteknologi for økonomisk storskalaproduksjon med standard- eller spesialemballasje.

I produksjonen av våre fjærer bruker vi toppmoderne kamerateknologi for å sikre produksjonsprosessen og samsvar med fjærtoleranser. I tillegg til teknisk renslighet er vi også kjent med kravene til organisk og biologisk renslighet innen medisinsk teknologi.

Lansetter til prøvetaking

Kompresjonsfjærer samt stansede og formede detaljer er vanligvis en integrert komponent i blodlansetttestenheter. Disse komponentene leverer kritisk nøyaktighet med sertifisert teknisk renhet og brukes for å gi trygg tilgang til blodet. Vårt kontrollerte «clean-room» produksjonsmiljø sikrer funksjonen og renheten til våre fjærer, stansede- og formede detaljer. Konsekvent kvalitetsstyring oppnås gjennom spesialdesignede vaske- og pakkekonsepter. Våre medisinske produksjonsevner har en høy grad av automatisering, noe som muliggjør effektiv serieproduksjon skreddersydd til dine prosjektkrav.

Trykkfjærer

Trykkfjærer

Trykkfjærer

Konstantkraftfjærer

Stansede fjærdetaljer

Trykkfjærer

Konstantkraftfjærer

Stansede fjærdetaljer

Kontinuerlig glukosemåling (CGM)

For kontinuerlig glukosemåling plasseres en sensor under huden. Den siste generasjonen av Continues Glucose Monitoring (CGM)-enheter bruker et feste som styres av konstantkraftfjærer eller trykkfjærer. Nøyaktig beregnet dreiemoment og trykkraft sørger for at sensoren er festet sikkert og komfortabelt.

Bærekraft er prioritert av Lesjöfors. Vi overvåker kontinuerlig vårt miljøfotavtrykk gjennom dataanalyser av våre produksjonsanlegg og våre lokale forsyningskjeder.

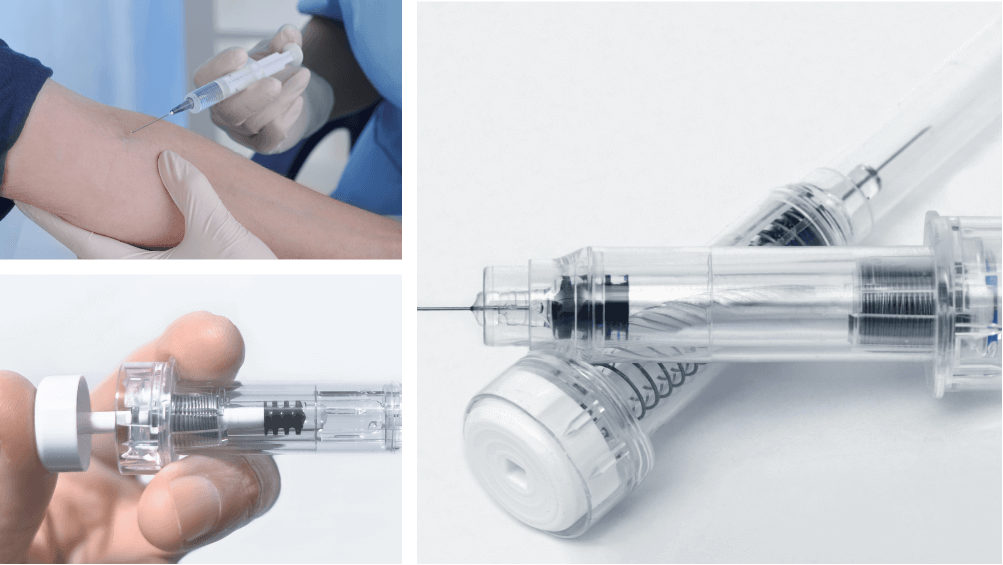

Sprøyter

Sprøyter innen medisinsk teknologi benytter hovedsakelig trykkfjærer. Utløser- og tilbaketrekkingsmekanismer for sikkerhetssprøyter, eller nåleskjold, styres av fjærteknologi. Avhengig av applikasjon og spesifikasjon, konfigurerer og beregner vi optimal materialkvalitet og fjærdesign.

I hovedsak brukes rustfrie stålmaterialer i forskjellige kvaliteter og overflatefinisher. Helt fra oppstart av prosjektet tar vi hensyn til fjærseparasjon, renhetskrav og pakking samt videre bearbeiding av fjæren i sluttmonteringsprosessen.

Trykkfjærer

Trykkfjærer

Trykkfjærer

Trykkfjærer

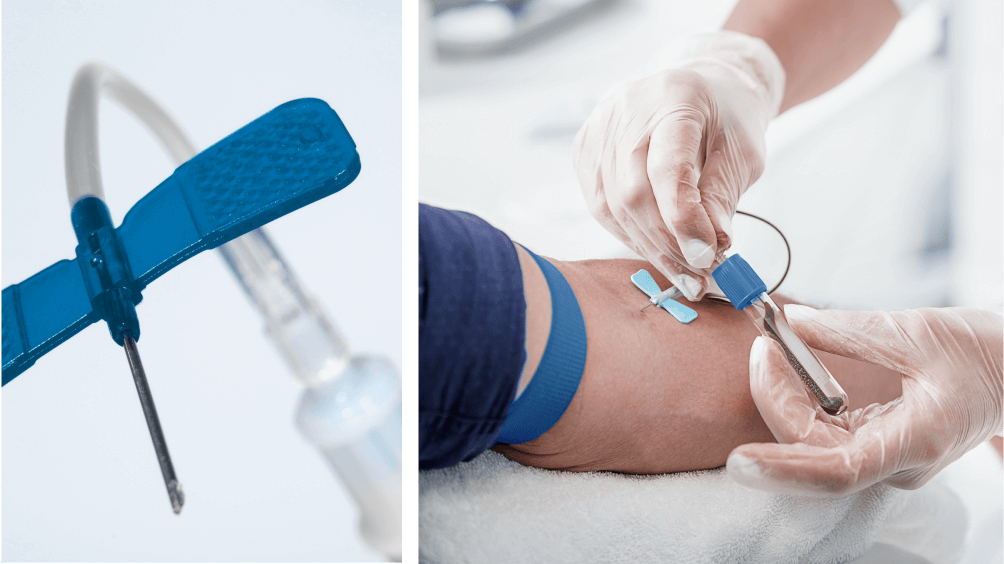

Blodprøvetaking og infusjonsteknologi

En av de nyeste og vanligste måtene for venøs blodinnsamling og infusjon er via kanyler med vinger («butterflys»). For å unngå utilsiktet overføring av infeksjon forårsaket av nålestikk, blir vingekanyler i økende grad utstyrt med tilbaketrekkingssystemer for nålen, eller nåleskjold. Tilbaketrekking av nålen styres av en trykkfjær.

Innen medisinsk teknologi for blodinnsamling jobber vi med de høyeste krav til teknisk og organisk eller biologisk renhet. Dette oppnår vi gjennom spesielle romforhold og automatisert fjærproduksjon.

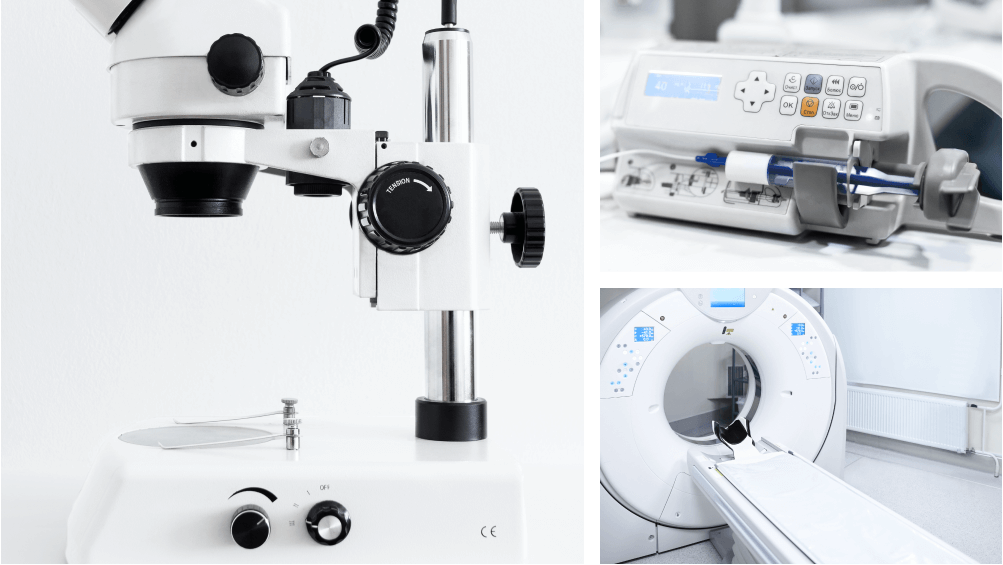

Diagnose- og laboratorieutstyr

I likhet med variasjonen av våre fjærer og stansede detaljer og formede detaljer, er bruksområdene innen diagnose- og laboratorieutstyr innen medisinsk teknologi nesten ubegrensede. Eksempler på bruken av våre fjærer kan være applikasjoner innen radiologi (MRT), blodprøvetakere og blodsukkermålere. Vårt utstyr innen medisinsk teknologi er også svært godt egnet for mellomstore og små produksjonspartier. Vår ekspertise innen fjærteknologi for diagnose- og laboratorieutstyr dekker hele produktutviklingsprosessen, fra produksjon av prøver til serieproduksjon.

Trykkfjærer

Drivfjærer

Stansede fjærdetaljer

Trykkfjærer

Stansede fjærdetaljer

Drivfjærer

Trykkfjærer

Inhalatorer og pumpespray

Avhengig av design brukes trykkfjærer, stansede detaljer og formede detaljer til inhalatorer og pumpesprayer innenfor medisin. Spesielt høye krav til teknisk renhet, organisk renhet og biologisk renhet gjør seg spesielt gjeldende her.

Vi produserer derfor disse produktene under spesielle renhets- og hygieniske forhold. Vi tilbyr en komplett renhetskjede fra valg av egnede materialer, produksjonsprosesser, emballasjekonsepter til renhetsanalyser. For dette produktområdet er vi en komplett leverandør og behersker alle ledd i verdikjeden.

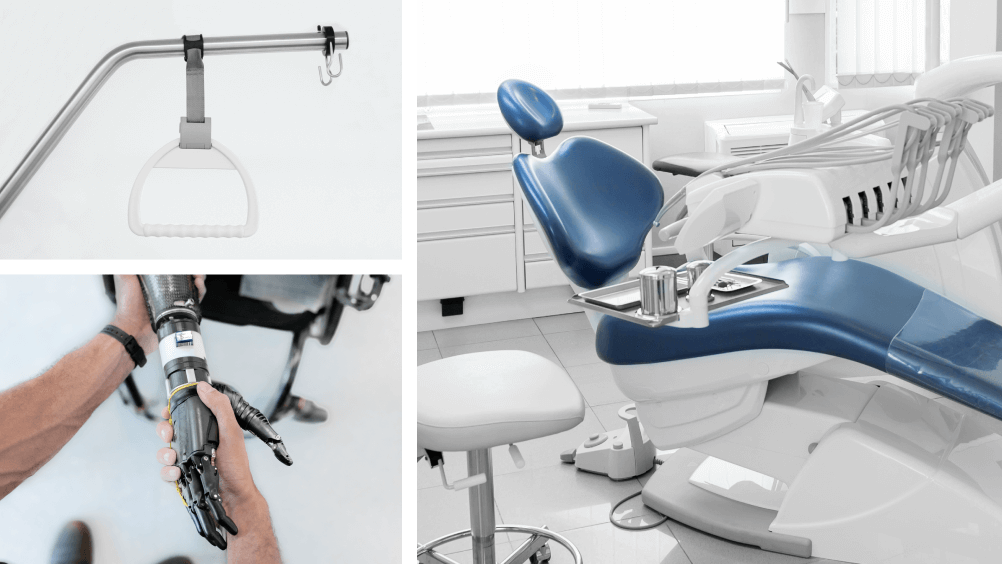

Medisinsk utstyr

Tekniske fjærer, gassfjærer og stansede detaljer og formede detaljer er en integrert del av medisinsk teknologi. De brukes i et bredt spekter av bruksområder, fra engangsartikler til store mengder.

Våre produkter brukes mye innen det medisinske miljøet, og noen eksempler inkluderer; trykkfjærer for sykehussenger, drivfjærer til klatrehjelpemidler, stansende detaljer til pasienttransportvogner, konstantkraftfjærer for automatiske falldeteksjonssystemer, tråddetaljer for proteser, formede detaljer for hørselsvern og mye mer.

Gassfjærer

Drivfjærer

Stansede detaljer

Drivfjærer

Stansede detaljer

Gass fjærer

Tråddetaljer

Trykkfjærer

Tråddetaljer

Trykkfjærer

Medisinske hygieneprodukter

Kravene innen hygiene blir stadig viktigere. Vi leverer til kunder innen medisinsk teknologi, kosmetikk og sterilisering. Våre fjærer spiller en stor rolle for å sikre at hygieneproduktene er trygge. I tillegg til kravene til renhet, spiller også nøyaktigheten og levetiden til våre fjærer en viktig rolle.

Medisinske hygieneprodukter inkluderer såpedispensere, desinfeksjonsdispensere, papirhåndkledispensere, duftdispensere og ulike kosmetiske applikasjoner. Med våre lokasjoner i Europa, Asia og USA oppfyller vi de høyeste standardene for kvalitet og levering.