Military Spring Manufacturers

High-performance, custom springs and components for Aerospace and Defense applications

Home » Industries » Aerospace and Defense

Aerospace and Defense component experts

Lesjöfors is a trusted global partner for military and defense spring solutions. We’ve been designing and manufacturing high-performance coil springs and wire forms for decades. Our parts are trusted in some of the toughest environments—on land, in the air, and at sea. We also produce pressings and gas springs that are built to last. Every piece is engineered for precision, reliability, and strength – in compliance with defense sector standards.

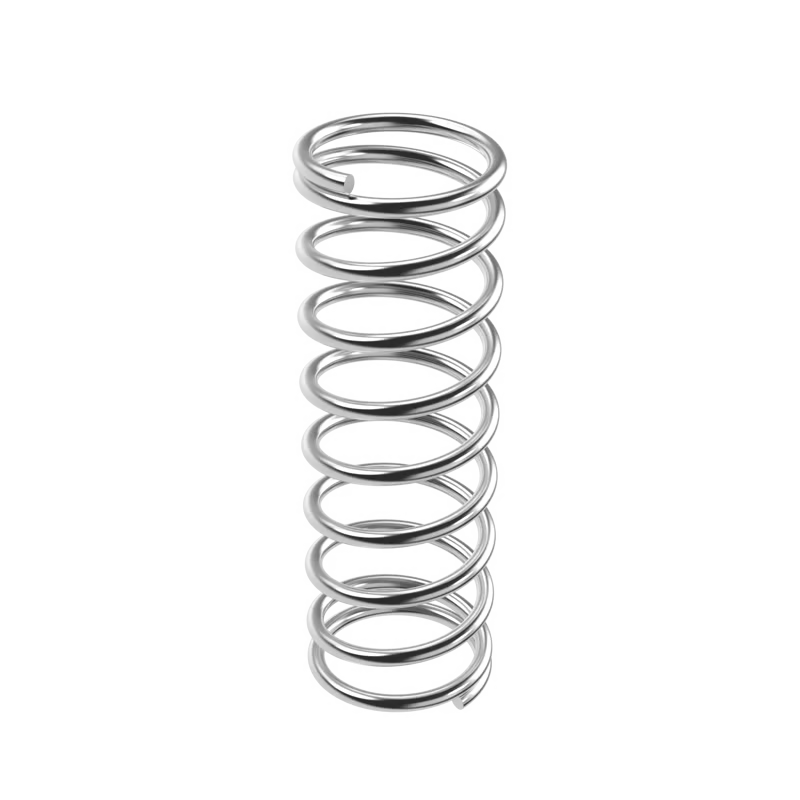

Compression Springs

Power Springs

Bending Parts

Custom Coil Springs and Wire Forms for the Military & Defense Sector

Lesjöfors specialises in designing and producing custom springs tailored to the unique demands of the military and defense sectors. From initial concept to finished product, our engineers collaborate closely with defense clients to deliver springs that meet extreme technical requirements and operational needs. Whether exposed to shock loads, high stress, or corrosive atmospheres, our springs perform with the utmost reliability.

Coil Springs, Wireforms, Pressings and Gas Springs for Extreme Conditions

Our springs are engineered for critical performance in environments where failure is not an option. We use premium materials and advanced manufacturing techniques to make parts you can rely on.

Our coil springs, wire forms, pressings, and gas springs are made for demanding conditions. They can take on heavy loads, high temperatures, and harsh environments. Each one is made to perform in aerospace, naval, and land-based military systems – environments where strength and reliability are essential.

Lesjöfors is a trusted partner in military applications, combining advanced production capabilities with a deep understanding of critical material requirements to meet stringent standards for anti-spark performance, Electromagnetic Compatibility (EMC), Electromagnetic Interference (EMI) mitigation, and Magnetic Signature Reduction (MSR) – delivering precision-engineered springs and pressings for the most demanding defense environments.

Compression Springs

Spring Design for the Military & Defense Sector

Superior Quality Through Precision Spring Design and Co-Development

Unrivalled Lead Time & Efficiencies

We combine world-class manufacturing with lean production methods. This allows us to deliver coil springs, wire forms, pressings, and gas spring solutions quickly and effectively. Each one is made to meet the needs of a wide range of applications, with no compromise on quality.

Production Runs to Suit All Needs

Finished Goods in Stock

Custom Packaging & Assembly

Bending parts

Spring Design for the Military & Defense Sector

Engineered for High Performance

Our military-grade springs and pressings are built for mission-critical reliability. Every product is engineered for peak performance, even in unpredictable environments.

Built to Endure Extreme Conditions

Precision Where it Matters Most

Highest Quality Materials

We work with a range of high-performance spring materials, such as alloys and specialist steels, that meet military and aerospace specifications, ensuring compliance, reliability and durability.

Types of Military Springs Used in the Defense Sector

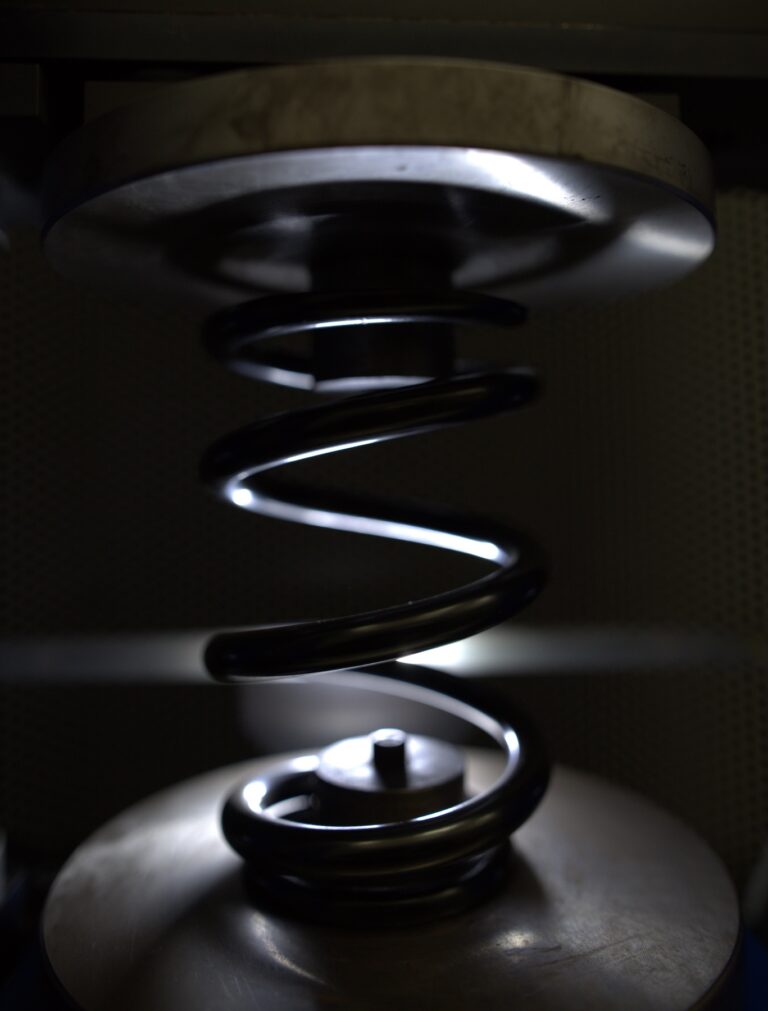

Compression Springs

Compression springs are used in shock absorption, stabilisation, and energy storage in a wide range of military systems.

Extension Springs

Extension springs are ideal for applications requiring resistance to pulling forces, such as control systems and mechanical linkages.

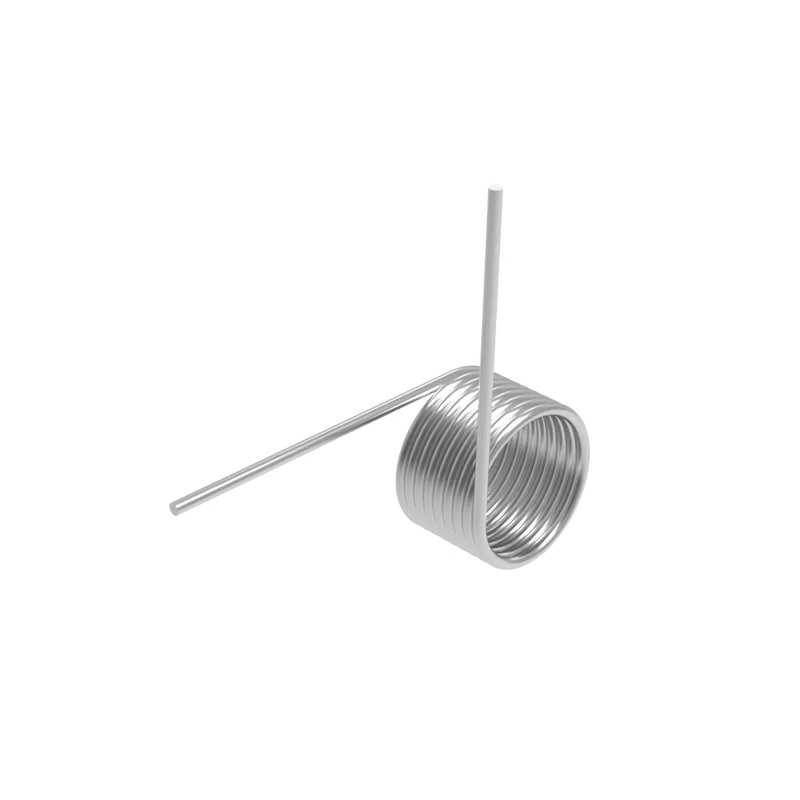

Torsion Springs

Torsion springs provide rotational force in systems like hatches, control arms, and airborne mechanisms.

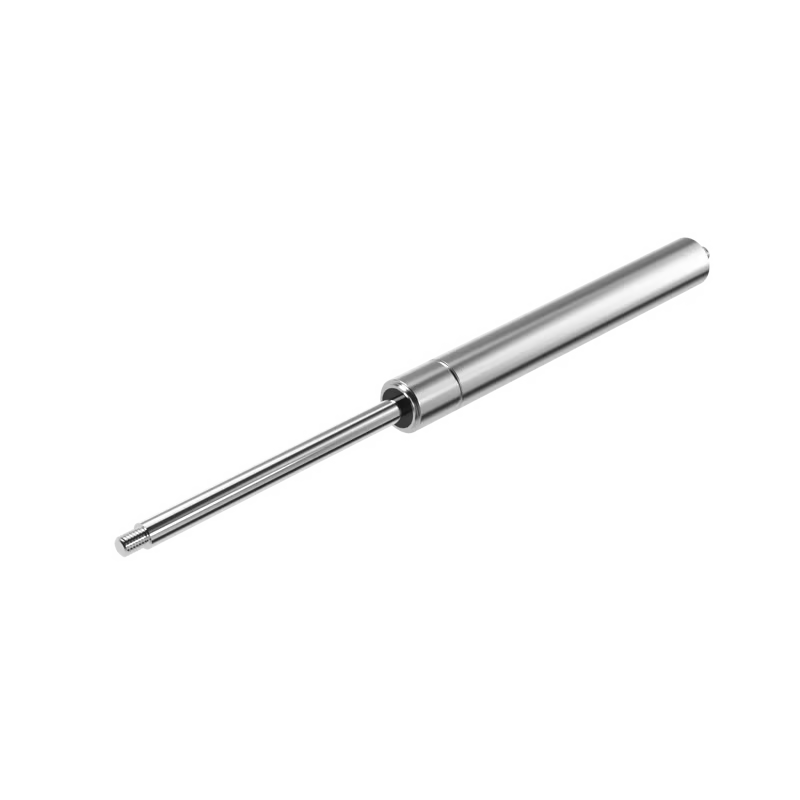

Gas Springs

Gas springs use compressed gas to provide controlled, adjustable force. They’re used for lifting, lowering, or dampening applications and play a key role in emergency escape systems, armored vehicle hatches and antenna deployment systems.

Wire Forms

Wire forms are custom-shaped wire components designed to meet specific mechanical requirements. They’re ideal for vehicle seating mechanisms and communication device components as well as clutch and braking linkages.

Pressings (Stampings)

Pressings, also known as stampings, are precision-stamped metal parts with complex shapes. Lesjöfors specializes in creating high-quality pressings. They’re ideal for tough electronic housings, tactical communication equipment, and armored vehicle assemblies.

Market Leaders in Military & Defense Springs

Lesjöfors is recognised worldwide for engineering excellence and supply reliability in the defense sector. We’ve spent decades delivering reliable results. Our quality is certified, and we work with clients around the world. They trust us to supply precision springs and stampings that work under pressure, every time.

Military Applications of Lesjöfors’ Springs

Aerospace systems

Naval applications

Our springs are made with specialist materials and coatings to resist corrosion. They’re built to last in harsh marine environments. You’ll find them in propulsion systems, gunfire control, missile launchers and sonar applications.

Armoured vehicles

Our springs support suspension systems, seating, hatch controls, and braking systems. They’re also used in other critical parts. Each one is designed for shock absorption and reliable performance on rugged terrain.

Missile systems and rocket motors

Defense electronics and communication equipment

Small arms and squad support weapons

Safety and emergency systems

Other specialised applications

Internationally Recognised Quality Standards

Lesjöfors springs are manufactured in accordance with major defense and aerospace standards. Our springs and stampings range from 0.01m to 80 mm+, providing solutions for every high-performance defense function.

- ISO 9001

- ISO 14001

- ISO 45001

- IATF 16949 (where applicable)

- DIN and other international defense specifications

We meet or exceed the standards required by defense clients across the UK, Europe, and the US, with full traceability and documentation.

Engineering Excellence & World-Class Manufacturing

Our in-house engineering teams and modern facilities enable full control over the entire production process, from initial design to final inspection. We offer:

- Advanced spring coiling, wire forming, pressing and stamping technologies

- Material testing and certification

- CNC machining and in-house tooling

- Assembly and finishing

- Rigorous quality assurance systems

Compression Springs

Compression Springs

Highest Quality Materials

By delivering springs and pressings made from non-ferrous materials—crucial for meeting anti-spark standards and reducing explosion risks—Lesjöfors is uniquely equipped to meet the specialised requirements of military connector components.

All our products use only proven, high-performance materials, selected to meet the standards of the defense industry. From non-magnetic materials, corrosion-resistant stainless steels to nickel alloys and high-tensile carbon steels, our materials ensure performance under pressure, and over time.

Precision Custom Springs

The Process

Every spring starts with a detailed engineering brief and feasibility review to ensure the right approach from the outset.

Precision Manufacturing

Our use of advanced CNC coiling and forming equipment guarantees high accuracy and consistent quality.

Heat Treatment

Quality Control

Gas Springs

Power Springs

Wire Forms

Springs, Wireforms and Pressings: The Future of the Defense Sector

How to Order Custom Coil Springs, Wireforms and Pressings

Here at Lesjöfors, our process is designed to be responsive, clear, and collaborative. Our team supports you from concept through to completion:

- Discuss your requirements with our experienced engineers.

- Receive a tailored design and technical proposal.

- Approve prototypes and move to production.

- Receive regular updates and full traceability throughout.

Your Dedicated Account Manager

Every Lesjöfors defense client is supported by a dedicated account manager, who is your direct point of contact for all technical and commercial matters. They’ll guide you through the process, from initial design to final delivery, ensuring clear communication and dependable service throughout.

Order Your Custom Springs, Wireforms and Pressings Today

Get in touch with defense spring experts today. Whether you need design input, technical guidance, or a fast-turnaround solution, we’re here to deliver precision-engineered results you can rely on.

Military Springs FAQs

What materials are used in Lesjöfors’ military and defense springs?

We use stainless steel, high-tensile steel, Inconel®, and other specialist alloys suited to high-load, corrosive, and extreme-temperature environments.