Industrial Gas Spring Solutions

Precision-Engineered Standard Stock & Custom Springs

At Lesjöfors, we offer one of the most extensive ranges of gas springs in the industry, with 1000s of standard options compatible with hundreds of end fittings and accessories. For specialised requirements, we also provide custom-engineered solutions tailored to exact specifications.

With global manufacturing, expert support, and a commitment to quality, we deliver performance reliability across multiple industries as the trusted partner for gas spring solutions.

Types of Industrial Gas Springs

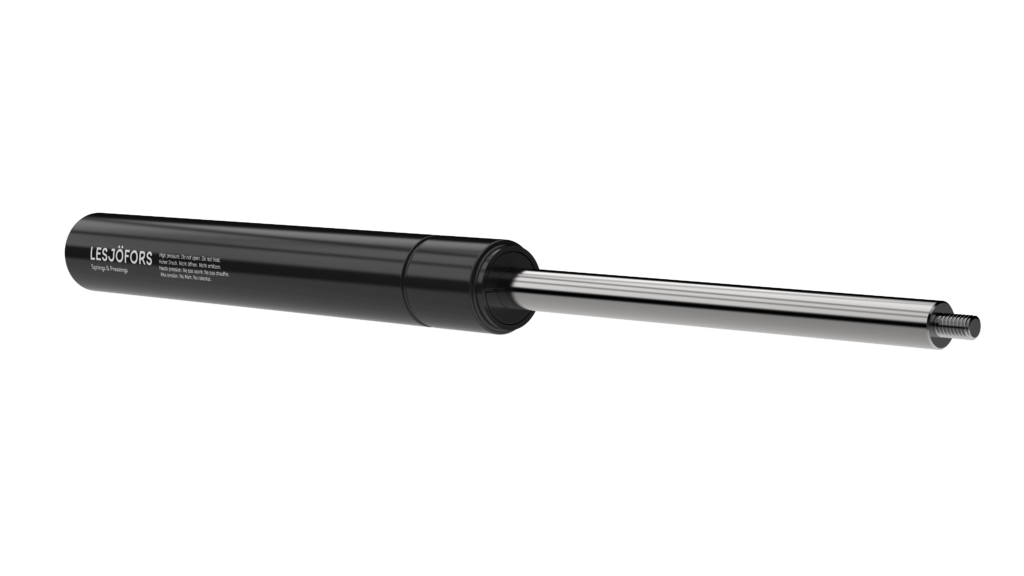

Gas Spring

Uses oil to dampen stroke at the end of movement. Standard and custom-designed options available. Commonly called compression gas spring.

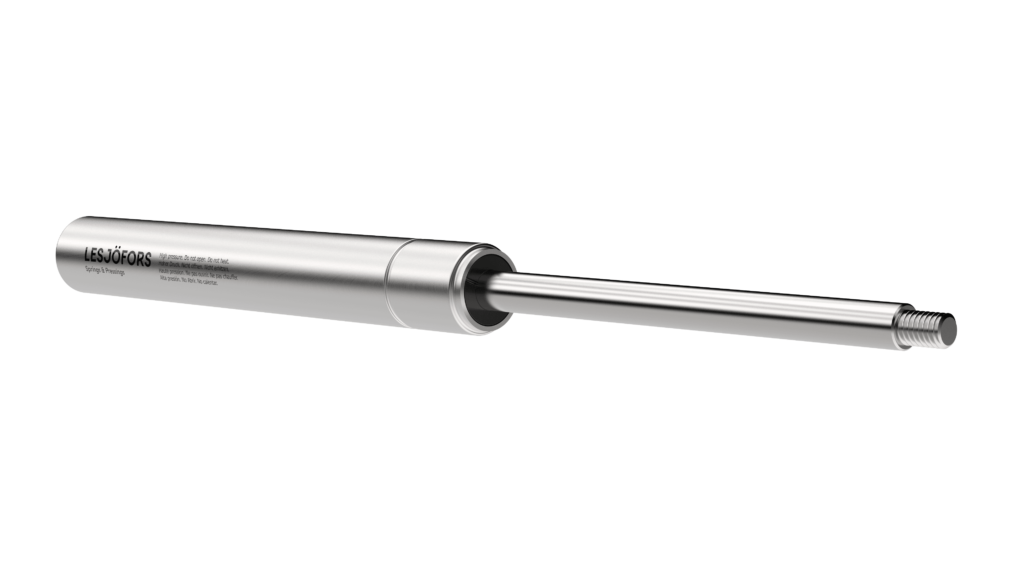

Stainless Steel Gas Spring

Ideal for corrosive environments. Can be produced in hydraulic, pin-locking and traction type designs. Standard and custom options available.

Traction Gas Spring

Works in pulling (tension) direction. Standard and custom-designed options available.

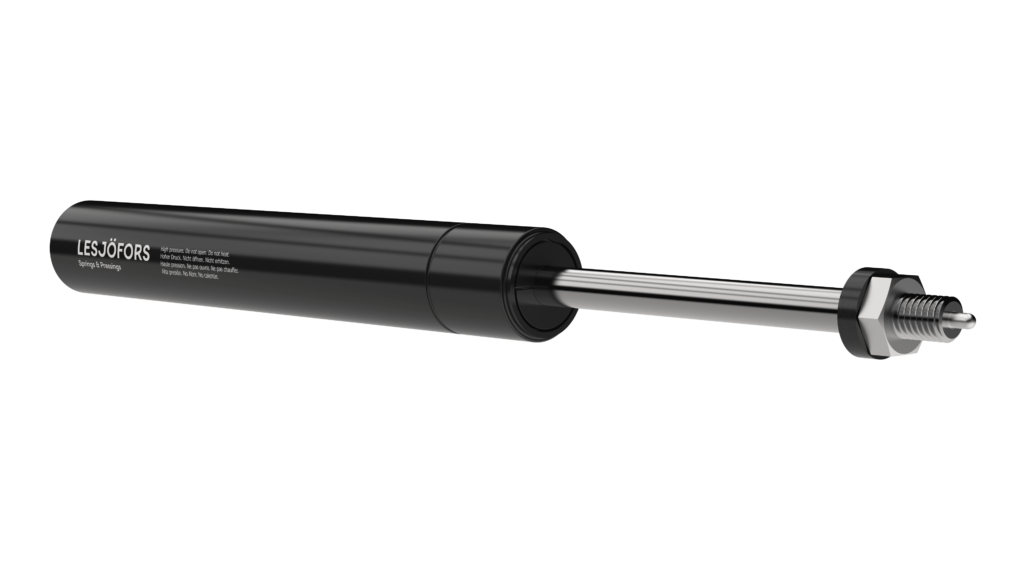

Lockable Gas Spring

Uses a special piston to lock the spring in any position along the stroke. Standard and custom-designed options available.

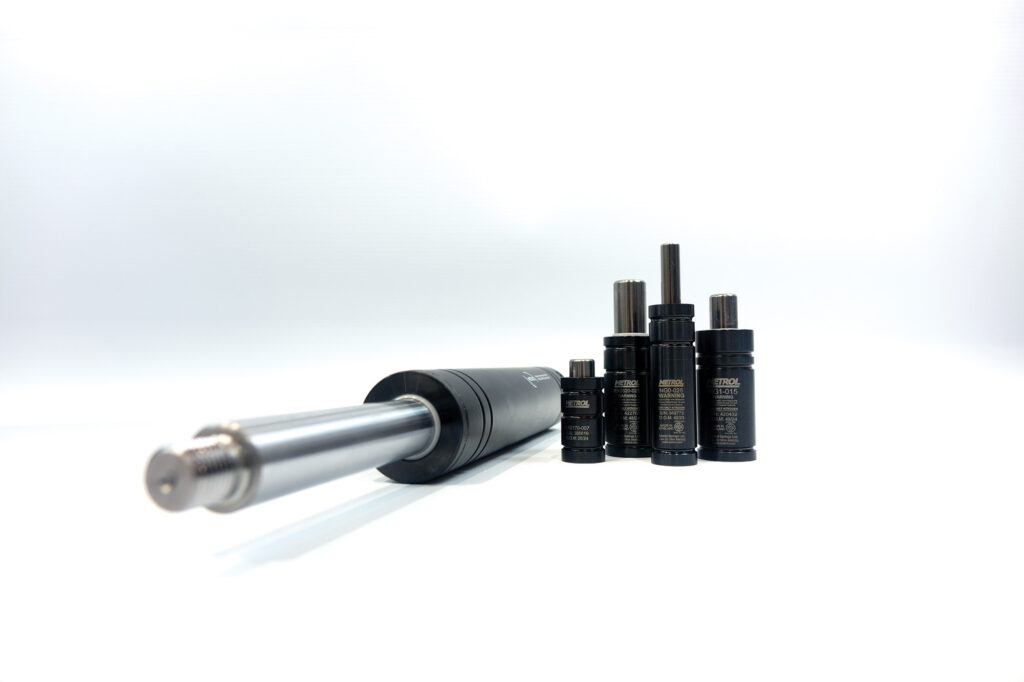

NitroSprings

Using compressed nitrogen and advanced nitro spring technology delivering forces up to

300,000N with stroke lengths ranging from 7mm to 2,000m. Compliant with PED 68/2014/EU.

Dynamic Gas Spring

Speed and damping controlled by a slot in the cylinder wall. Standard and custom-designed options available.

Applications of Industrial Gas Springs

Our gas springs (or gas struts) have a wide range of applications in diverse industries, from automotive to agriculture, medical to machines.

Hydraulic gas springs are the most common type, using oil to control extension speed and stroke damping. They ensure reliable motion and are ideal for doors, hatches, ventilation systems, and furniture.

Stainless steel springs are ideal for corrosive environments. They’re commonly used in boat hatches, food processing machinery, and medical lab equipment.

Traction gas springs operate in tension, ideal for applications such as folding access ramps, retractable staircases, and overhead hatches. They offer reliable movement when precise tension control is needed.

Our lockable gas springs provide secure position locking in adjustable applications like hospital beds, chairs, backrests, and tables. They ensure safe, reliable operations.

Precision performance in high-demand and heavy duty applications, our nitrogen gas springs are used for lift, counterbalance, tensioning, clamping, damping, suspension, anti-vibration, safety overload devices and ejection applications.

Our dynamic gas springs are ideal for closing mechanisms of car boots, car bonnets, gates, and doors. They ensure smooth operation with controlled extension speed and damping.

Why choose us as your Stock Gas Spring supplier?

- Market-leading springs and pressings manufacturer

- Widest product range in the industry

- Online ordering with 24-hour delivery

- Gas spring configurator for custom designs

- Helpful and responsive customer service

Custom Gas Spring design

Lesjöfors specialises in custom gas spring design, offering tailored solutions for unique requirements across industries such as automotive, construction, agriculture, defense, and medical. With over 40 years of gas spring expertise, we offer engineering support from concept and prototyping to production, delivering high-performance custom products that meet the highest standards of quality and reliability.

We also offer an online Gas Spring Configurator, allowing you to order simple custom products quickly and effectively.

Choosing the right Industrial Gas Spring

To ensure reliable performance in your application, there are some technical factors to consider when choosing a gas spring:

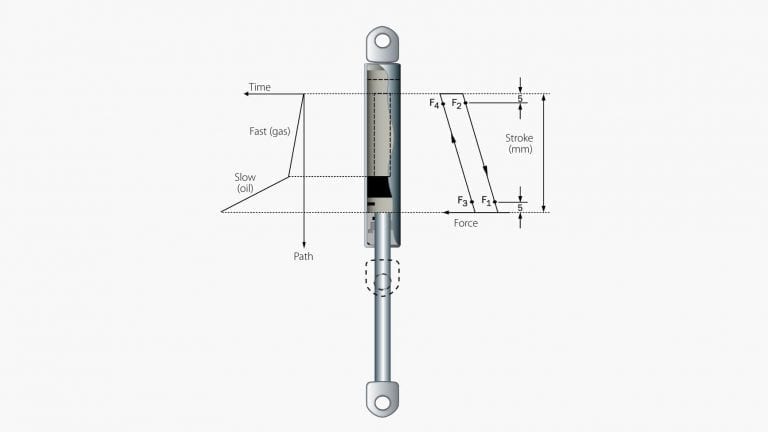

Force requirements

Accurately calculating force requirements ensures gas springs deliver the right amount of control and movement.

Stroke length

The stroke length should match the travel distance needed for smooth and efficient operation.

Mounting orientation

Proper mounting orientation helps maintain consistent performance and extends the gas spring’s lifespan.

Environmental conditions

Considering temperature and potential corrosion ensures gas springs remain durable and perform well in harsh environments.

Precision-engineered Gas Springs: quality & compliance

Our precision-engineered gas springs are designed to meet the highest manufacturing standards, including compliance with PED 2014/68/EU. We have rigorous testing procedures in place, ensuring safety, performance and reliability in every product manufactured in our global network of sites. Professionals trust our products across industries, including medical, automotive, and construction.

You’ll find Lesjöfors gas springs in diverse applications, from award-winning boats to motorhome manufacturing, and vehicle accessibility ramps.

Standard Stock & Custom Gas Spring solutions

With 1000s of items in stock, we’re proud to have one of the most extensive ranges of gas springs in Europe.

Enquire about Custom Gas Springs

For specialised requirements, our expert engineers can create custom gas spring solutions to meet your exact requirements.

Latest News

February 10, 2026

Lesjöfors strengthens its digital engineering capabilities with the latest enhancement to its industry-leading Gas Spring Configurator: a NEW Share option that enables faster, more efficient collaboration across teams, departments, and disciplines.

February 6, 2026

Beijer Alma, Lesjofors Group’s parent company, has published its 2025 year-end results, showing stable revenue growth, improved profitability and stronger cash flow despite a challenging market.

January 27, 2026

Johnny Alvarsson has been appointed Acting President and CEO of Beijer Alma AB, the parent company of the Lesjöfors Group, and will also serve as CEO of the Lesjöfors Group.