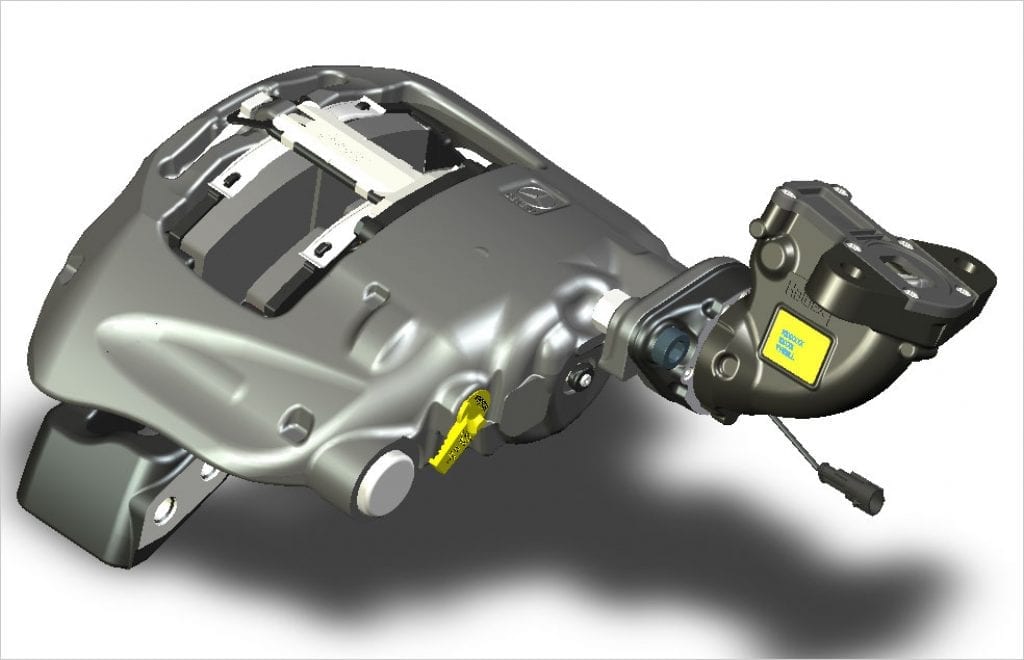

ModulT is designed as a complete program for both tractors and pulled units, extended in steps. At the top of the current range is the heavy-duty version of the 22.5-inch application with a maximum brake torque of 30 kNm. All ModulT brakes utilize Haldex’s special single-tappet mechanism, which offers two key benefits. The first is extensive support and uniform pressure on the brake pads. The second is a weight-optimized design that is not a single gram heavier than necessary.

Components from several companies in our group

In the three-year long development process, Lesjöfors has contributed with spring competence, design and manufacture of several different components. Lesjöfors Banddetaljer in Värnamo is supplying six stampings, Lesjöfors Industrifjädrar in Nordmarkshyttan and Herrljunga are supplying one wire form and six different springs. Haldex offers several different models of the disc brake and the components vary some in the different models.

Lesjöfors Banddetaljer has also supplied components to the earlier version of the ModelT disc brake; some of these are carry-overs with no need for further development, while other components are completely new. Johan Gannerud, Technical Sales, comments on the project:

“We are happy to support Haldex in this prestigious development project with our wide expertise in the springs and stampings field.”

Various springs in a narrow space

Lesjöfors Industrifjädrar is supplying two compression springs as well as two larger and two smaller oneway springs to the tailored disc brake. Henrik Berner, Technical Sales, comments on their spring design:

“We got involved on an early stage in the project and could therefore contribute with technical advice, prototypes and testing. This is a great example on how we can adjust several springs into a very limited space.”