Velbert, Germany – Stefan Musslinder, technical manager of the Lesjöfors Group, moderated the technology days May 8-10 in Velbert, where our German subsidiary Velleuer is located. One of the most important goals of the meeting was to get everyone to know each other’s companies better including technical expertise, production capacity and spring range. And of course also to get a personal relationship with fellow co-workers across the group.

“To arrange these technology meetings on a regular basis is very important for us a group. My impression is that the participants are very content with the arrangement. They get the chance to deepen their personal network and also a good amount of new knowledge to bring back home”, says Stefan Musslinder.

Study visit, force measurement and impact of heat treating springs

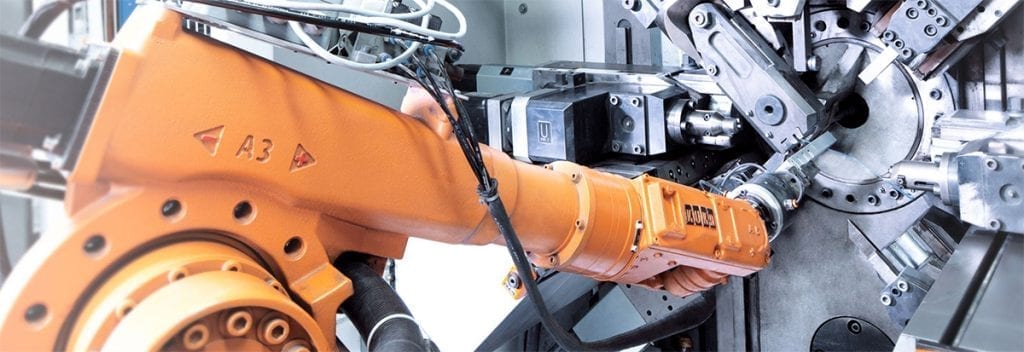

The conference also included a study visit to Wafios’ in-house exhibition where the group got a demonstration of the latest machinery and technologies from the company. Afterwards, different technological topics were discussed such as different ways of hardening spring material, results of a comparative force measurement, impact of heat treating compression springs after shot peening and much more. There were also an important discussion about what common terminology the group should use for different spring types.

Useful contacts developed

At the last day of the conference, Frank Jahn, MD of Velleuer, took the participants on a much appreciated factory tour at Velleuer. One of the things that impressed the most was the variety of different machine types and the skills to run them.

“We take turns on where we locate our technical meetings so that everyone gets to visit all production units. The factory tours give us all a good chance to experience the individual capabilities of every company in the group and ask questions. Almost everyone picks some ideas up that are possible to realize in their own production”, says Stefan Musslinder.